Madurkathi mats and crafts begin in the wetlands of Bengal — with a reed, a weaver, and a rhythm that has not changed for generations.

What is madurkathi?

Madurkathi (madur kathi) is a type of sedge or reed that grows in the marshy, low-lying areas of West Bengal and Bangladesh. Its scientific name is Cyperus tegetum. The reed is soft, flexible, and durable when dried — ideal for weaving mats, baskets, and other household objects. The craft of madurkathi weaving is concentrated in districts like Cooch Behar, Nadia, Murshidabad, and North 24 Parganas, where communities have depended on it for livelihood and cultural identity for centuries.

Step 1: Harvesting the reed

Harvesting is seasonal and often done by hand. Weavers or harvesters wade into the wetlands and cut the reed at the base. The best quality comes from reeds that are mature but not too old — timing matters. After cutting, the reeds are bundled and carried to the village. The harvest is tied to the monsoon and the natural cycle of the marsh; there is no industrial farming here. This connection to the land is part of why madurkathi feels so grounded and authentic.

Step 2: Drying and preparation

The reeds are spread in the sun to dry. Drying can take several days and must be even to avoid mould or brittleness. Once dry, the reeds are sorted by thickness and length. Some weavers split the reed into finer strands for more delicate work; others use the full stem for robust mats. The prepared reed is stored in a dry place until it is time to weave. In some regions, reeds are also dyed using natural colours — turmeric, indigo, or other plant-based dyes — to create patterns or borders. This step is optional but adds to the beauty and variety of the final product.

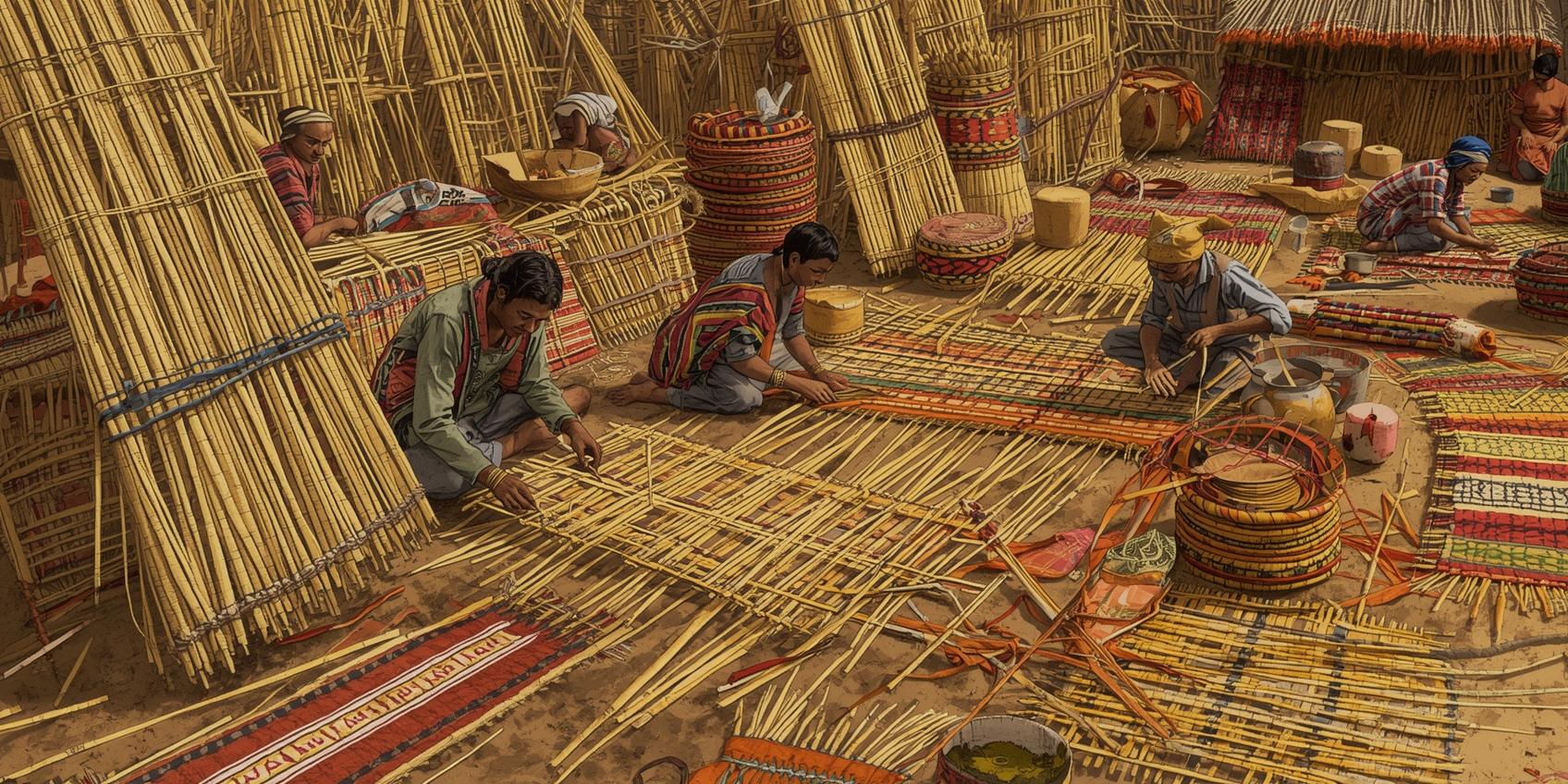

Step 3: Weaving

Weaving is done on a simple frame loom or sometimes on a pit loom. The weaver works at home, often with family members helping. The basic motion is over-under: the weft (horizontal strands) is passed through the warp (vertical or base strands) to build the mat row by row. For flat mats, the weave is tight and even. For baskets or three-dimensional forms, the weaver builds up the sides by changing the angle and tension of the weave. Speed varies with complexity; a large, fine mat can take many days. There are no machines — only hands, eyes, and the accumulated skill of years.

Step 4: Finishing

Once the mat or craft is woven, the edges are finished by folding, binding, or stitching so that they do not fray. Some mats are given a final trim or wash. The result is a product that is natural, biodegradable, and built to last with care. Madurkathi mats are naturally cooling and breathable — ideal for sitting, sleeping, or yoga in warm climates. They also age with a soft patina that many find beautiful.

Why the process matters

Understanding the madurkathi weaving process helps us appreciate why these pieces cannot be rushed or mass-produced. Every step is human-paced and tied to the environment. When we at House of Dhrti commission mats and crafts from our partner weavers, we honour that pace. We pay fairly, we give lead time, and we never ask for shortcuts. When you buy a madurkathi mat or basket from us, you are buying the result of that entire journey — from wetland to your home.